Types and components of CPAP machine

CPAP machine in an essential component of all level II and Level III NICU. In this webcast we would learn the components and types of CPAP machines. Cleaning, disinfection and Troubleshoot with the use of CPAP machine will also be discussed.

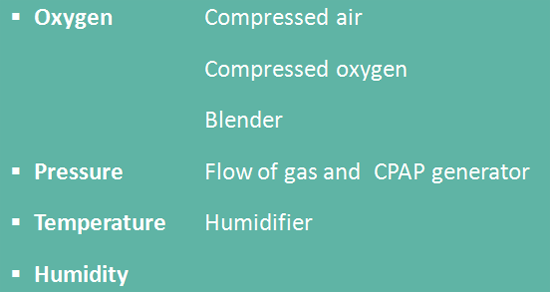

Delivering CPAP to a newborn involves giving oxygen ranging from 21 % to 100%, CPAP pressures 4 to 7 cms of water, flow of air oxygen mixture at 2 to 7 liters per min and the required air oxygen mixture at a temperature of 37C and a relative humidity of 100% to the newborn nares.

For delivering oxygen 21 to 100% one would need a compressed air source such as an air compressor or a centrralized gas source, compressed oxygen source such as an oxygen cylinder or a centralized gas source and a blender to mix the pressurized air and oxygen to the desired fractional oxygen concentration. To generate CPAP there is a need for flow of air and oxygen mixture in a closed tube and the presence of a CPAP generator. For delivering warm and humdifier air oxygen to the nares, there is also a need for servo controlled humidifier

This figure shows the components of a ideal Bubble CPAP set up. Air and oxygen, Blender, flow meter, Servo humidifier, inspiratory limb, nasal interface, expiratory limb, bubble chamber.

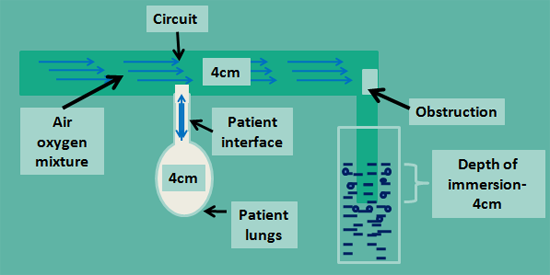

This figure illustrates the generation of a CPAP pressures in a closed tube connected to the lung. Air oxygen mixture is flowing in a T piece connected to a lung. As the gas flows in the T piece, air from the lung will be sucked into the tube due to bernoillue principle. When an obstruction is built in the T piece as the gas is flowing in the tube, pressure builds in the T piece and gas will flow into the lungs till the pressure in the lungs equals the pressure that is built in the T piece. The pressure built in the T piece is proportional to the degree of obstruction or to the flow of gases in the closed T piece. The obstruction to gas flow in the T piece can also be achieved by immersing one end of the T piece in a chamber of water. The pressure generated in the T piece and in the lung is equal to the depth of immersion of the end of T piece. The greater the depth of immersion, greater is the pressure built in the T piece. The depth of immersion of the T piece inside water from the water level is the pressure generated in the T piece provided the gas mixture is bubbling out from the pressure generator or the water chamber.

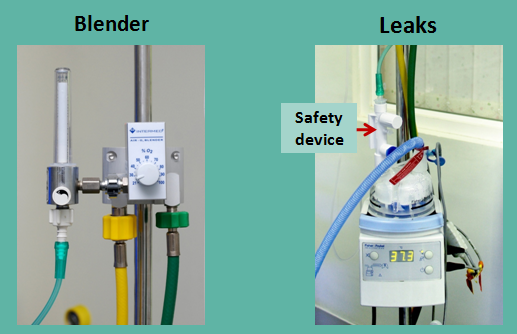

Compressed oxygen has 100% fractional oxygen and compressed air has 21% of fractional oxygen concentration. A blender mixes the compressed air and compressed oxygen to desired fractional oxygen concentration from 21% to 100% dependending the desired FiO2 one sets on the blender. The amount of gas coming out of the blender is to be set by the flow meter that is fixed at the outlet of the Blender.. So the blender is used to titrate the FiO2 of the gas mixture and Flow meter is used to titrate the amount of gas mixture that is allowed to flow in the T piece.

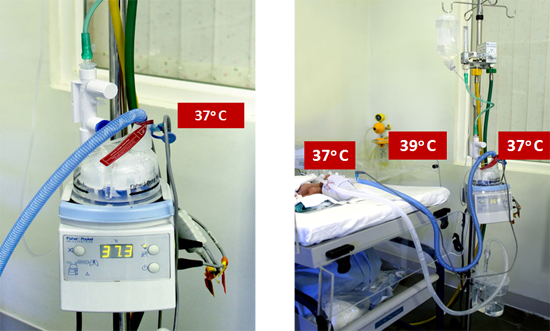

A servo humidifer delivers the gas mixture to the newborn nares to 37 C and at a relative humidity of 100%. To do this function servo humidifiers are autoset for the exit of gas form the humidifier chamber at 37 C and reach a temperature 39 C inside the inspiratory of the CPAP circuit. The heating of gases to 37 C occurs in the water chamber of the humidifier and gas heating from 37 to 39 C in the inspiratory limb occurs by a heating element present in the inspiratory limb. As the length of the heating element is restricted in the inspiratory limb upto a few cms away from the nares, there is drop in gas temperature from 39 C to approximately 37 C in the inpiratory limb and just before reaching the nares of the newborn. To ensure this estimated drop of gas temperature in the inspiratory limb, the last segment of the inspiratory limb should be inside the radiant warmer. The gas that exits from the water chamber is at a relative humidity of 100% and as the gas gets heated in the inspiratory limb (from 37 to 39C) there is a drop in relative humidity. Again in the last segment of inspiratory as gas temperature comes back to 37 C, equals to temperature that is exit from the water chamber, gas reaching the newborn nares will be at 100 RH.

There are three types of CPAP machines depending the type of pressure generators. In a bubble CPAP, CPAP pressure is generated by a bubble or water chamber, in a ventilator CPAP is generated by a valve/obturator in the expiratory limb of the expiratory circuit and CPAP is generated at the peculiar nasal interface by degree of gas flow and fixed obstructive mechanism fitted in the nasal interface.

When using CPAP machine always prefer a disposable circuit that is best suited for the type of machine.

There is no need for routine scheduled replacement of the CPAP circuits. One circuit can be used for One Baby.

Always fill the water chamber of the humidifier with distilled water and using the auto fill option availabe in the disposable circuits Clean the CPAP machine with a soft cloth and ensure wate logging in the CPAP circuit at all times

The major problems one faces when using a CPAP machine are: Alarms and malfunctioning of the blender, leaks in the circuit, condensation and water logging in the circuit and inadvervent delivery of high pressures.

The alarms from the blender occurs due to disprecency in the gas pressures of oxygen and air reaching the blender. One need to replace the oxygen gas cyclinder or cylinders and or troubleshoot the air compressor to rectify the alarms from the blenders. The blender needs recalibration once in every 3 months. The common sites of leaks in the CPAP circuit are at the inlet safety device, at the inlets of the temperature probes or heater wires and at the mouth of the newborn. The device when working appropraitely avoids excess and inadvertant delivery of high pressures to the newborn.

The water logging in the inspiratory limb is avoided by a working heater wire, ensuring environmental temperature between 28 to 30 C, preventing the placement of temperature probe under the radiant warmer and ensuring the placement of the terminal segment of inspiratory limb under the radiant warmer. The temperature probe should be covered with an insulating cloth or gauge if it falls inside an incubator or radiant warmer. The pressure generating water chamber should always be placed below the level of the newborn. If the water level increases excess water will drain to the side chamber. However if water evapourates the water level would fall, resulting in reduced depth of immersion and reduced pressure generation in the CPAP circuit.

In conclusion a CPAP machine is a combination fo pressure generator, delivery of fractional oxygen from 21 to 100% and delivery of warm and humidified gases to the newborn nares. In a bubble CPAP machine the pressure generator is the bubble chamber, fractional oxygen to desired level is achieved with compressed air and oxygen and a blender, warming and humidifcatin of gases is achieved with a servo humidifier.

- Introduction...

- 1. Requirements fo...

- 2. Requirements fo...

- 3. Simple bubble C...

- 4. CPAP generator...

- 5. Oxygen...

- 6. Humidifier...

- 7. Types of CPAP m...

- 8. Cleaning and di...

- 9. Troubleshoot...

- 10. Troubleshoot 0...

- 11. Condensation a...

- 12. Summary...

|

|

Introduction

DR. SRINIVAS MURKI

MD, DM (Neonatology)

Consultant Neonatologist

Fernandez Hospital

Hyderguda, Hyderabad

1. Requirements for CPAP

2. Requirements for CPAP

3. Simple bubble CPAP setup and components

4. CPAP generator

5. Oxygen

6. Humidifier

7. Types of CPAP machines

► Bubble CPAP machine

► Flow driver CPAP machine

► Ventilator CPAP

8. Cleaning and disinfection

► Always use disposable circuits

► No need to replace circuit routinely

► Fill the humidifier chamber with distilled water

► Use the auto-fill option for filling the chamber

► Clean the equipment with a soft cloth and

► Ensure there is no water logging

9. Troubleshoot

► Alarm from the blender

► Malfunctioning of blender

► Leaks in the circuit

► Condensation in the inspiratory limb

► No condensation in the expiratory limb

► Inadvertent delivery of high pressures

10. Troubleshoot 01

11. Condensation and water

12. Summary